algorithmic modeling for Rhino

Hey guys,

I've been watching videos out there on using grasshopper to generate g-code for 3-axis milling and i was wondering if anyone has used grasshopper to create a g-code for a hotwire foam cutter? I'm currently building a 4 axis hotwire cutter and since rhino is my main program for design, being able to use gh to create a gcode for mach3 would be awesome. If anyone knows anything about this please let me know!

Thanks!

Views: 6773

Replies to This Discussion

-

can you upload any gcode file that works with your cutter ?

-

-

I guess thats part of my problem right now, i'm trying to figure out what program i can use to generate a gcode that will work with a 4 axis system...so as of now i don't have any gcodes that will run 4 axis independently...if that makes sense

-

-

I guess a more simple way to word my question would be, Can you setup Grasshopper to create gcode for a hotwire (vs. the milling/drilling examples that are out there)

-

-

Here's my idea of it. I'm assuming that on a foam machine the wire is Y and X is in the plane of the table perpendicular to Y while Z is normal to the table and perpendicular to Y. Therefore one end of the wire is attached in the X-Z plane and the other end terminates in the A-B plane (or other letters of your choice).

Chris

- Attachments:

-

-

but to run gcode on any machine, code need some layout. I mean 3d gcode looks different, depending on manufacturer will :) Thats why we need some sample code which will work with kyle's cutter.

EDIT: I reminded myself "keyword" for this thread : post processor !

-

-

Yeah, you're right about that. I was just trying to illustrate that the geometry could in principle be reduced to Gcode .

-

-

Thanks for the help so far guys, i'll see if i can get a working sample file, i've gotten gcode running in mach3 but only for 3 axis not 4. What i'm trying to find is a way to beable to have a seperate "tool path" for each tower, since most programs that are producing gcode are based of a single cutting point like in milling.

-

-

There's a screen set for Mach3 for foam cutting. It looks like you use A and B axes for the parallel plane. Here's another link that should be helpful. The author expresses a concern about synchronizing the parallel plane when doing a taper but I believe Mach will automatically adjust for this when all of the axis moves are in the same block.

Chris

-

-

Yeah i've actually been using that screen set, its great...i haven't had much time today to work with the suggestions that have been made but tomorrow should be a solid day at it.

-

-

here you have some kind of gcode writer : (attachments)

Please read all my notes there - for your own safety ;]

I assume that 4d cnc cutter works like this , never seen such a cutter ;/

I don't know anything more about your cutter, so I decided not to apply any interpolation = prefix G01 (linear)

If there is possibility to interpolate with G02 or G03 its quite simple to add some script that changes interpolation depending on curvature.

Simulaton works perfectly for me ;]

- Attachments:

-

-

Wow, that is very helpful...i haven't had time to thoroughly go through the file yet but it looks to be very close to what i'm trying to do. Your assumption on how the hotwire cutter works is correct.

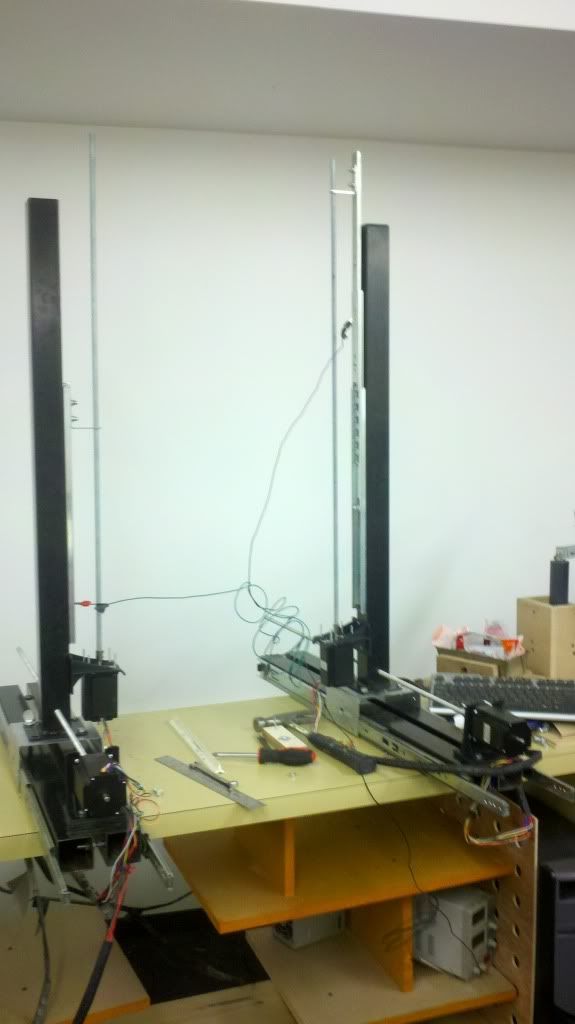

this is a picture of the cutter....the two towers are made to move independently, where the wires are connected represent the extremes of the hotwire itself. So unlike a cnc that runs a single continuous path, the hotwire has two seperate paths. I'm hoping to to try and work through the definition tonight, its alot for me to comprehend but hopefully i can figure out what everything means.

this is a picture of the cutter....the two towers are made to move independently, where the wires are connected represent the extremes of the hotwire itself. So unlike a cnc that runs a single continuous path, the hotwire has two seperate paths. I'm hoping to to try and work through the definition tonight, its alot for me to comprehend but hopefully i can figure out what everything means. -

-

remember that I decided to place material always on the middle plane. This can be changed but it seems to be most intuitive to place it like that.

There is a "straight line finder" based on closest point component, which can melt material non-unifomly - right path(AB) can move slower then left path, see point distribution on right path. I dont have now any idea how to make it better. Other point distributing can make geometry look like :

http://epinet.anu.edu.au/images/minimal_surfaces_soap_film.jpg?1317...

-

© 2024 Created by Scott Davidson.

Powered by

![]()